In Romania, Revolution 4.0 is postponed for now indefinitely. With a proportion of only 11 robots per 10,000 employees in the manufacturing industry, compared to the regional average of 60, our country is unacceptably late for the start.

In Romania, Revolution 4.0 is postponed for now indefinitely. With a proportion of only 11 robots per 10,000 employees in the manufacturing industry, compared to the regional average of 60, our country is unacceptably late for the start.

We are far behind not only the Western countries from the EU but also those of the former communist bloc:

- Slovenia – 110 robots per 10,000 employees in this sector

- The Czech Republic – 93

- Hungary – 57

- Poland – 28

In the EU, only Croatia (5 robots/10,000 employees) and Estonia (8) have a worse situation than Romania.

Foreign investment has brought new, state-of-the-art technologies to the countries that became members after 2004, which has propelled some of them even ahead of some of the strongest EU countries, in some sectors.

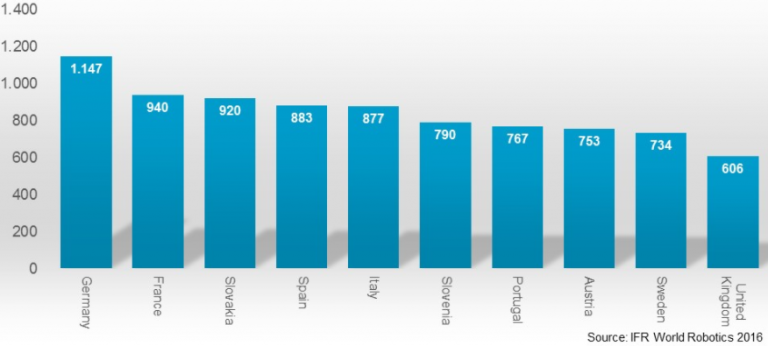

This is how Slovakia and the Czech Republic have surpassed the United Kingdom, for example, at the robot density index, both in the whole manufacturing industry and in the automotive sector, according to the latest International Robotics Federation (IRF) data.

That has not happened, though, in Romania, where the workforce is still too cheap to reach the inflection point when robots become more profitable, despite the serious shortage of skilled workforce on the labour market.

EU, highest average penetration rate of industrial robots

EU, highest average penetration rate of industrial robots

In the manufacturing industry, the average density at the global level is 69 robots per 10,000 employees involved in the production process in 2015. Europe has the highest average level in this field – 92 units compared to 86 units in the two Americas and 57 in Asia.

Out of the 22 countries with a higher density rate than this global average level, 14 are in the EU. Among them, Slovenia (with 103 robots per 10,000 employees), the Czech Republic (93) and Slovakia (79 robots).

The UK nearly missed the ranking, with only 71 robots per 10,000 employees:

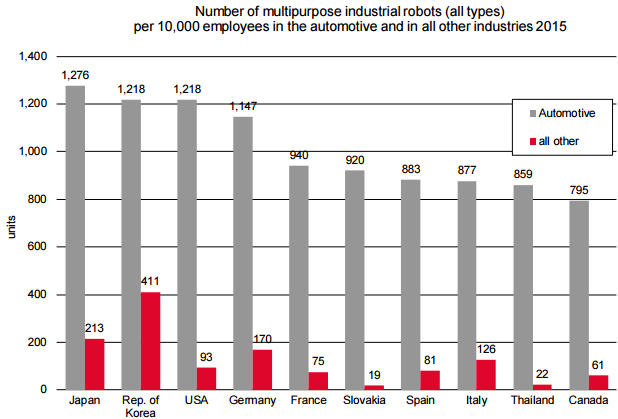

The high degree of robotization in Europe is also reflected in the automotive sector – of the Top 10 countries with the most industrial robots per 10,000 employees in this sector, half are from the European Union:

The high degree of robotization in Europe is also reflected in the automotive sector – of the Top 10 countries with the most industrial robots per 10,000 employees in this sector, half are from the European Union:

Slovakia, benefiting from the mix between low population (only approximately 5.5 million inhabitants), significant foreign investment and advanced technology, has a density at the whole industry level (excepting the automotive sector) of only 19 robots but also ranks in global top 10 robotic automotive industries.

Slovakia, benefiting from the mix between low population (only approximately 5.5 million inhabitants), significant foreign investment and advanced technology, has a density at the whole industry level (excepting the automotive sector) of only 19 robots but also ranks in global top 10 robotic automotive industries.

By comparison, the UK (with 33 robots per 10,000 employees at the whole industry level, excepting the automotive sector) is far behind Slovakia and other European countries in terms of automotive industry robotization:

The robot penetration rate at the whole industry level (excluding the automotive sector) is much lower and the highest rates are in the countries with an advanced electronics industry:

The robot penetration rate at the whole industry level (excluding the automotive sector) is much lower and the highest rates are in the countries with an advanced electronics industry:

- South Korea – 411 robots per 10,000 employees

- Japan – 213

- Germany – 170

- Taiwan – 159

- Sweden – 154

- Italy – 126

- Austria – 95

- USA – 93

The UK has only 33 robots installed per 10,000 employees at the whole industry level (which does not include the automotive sector).

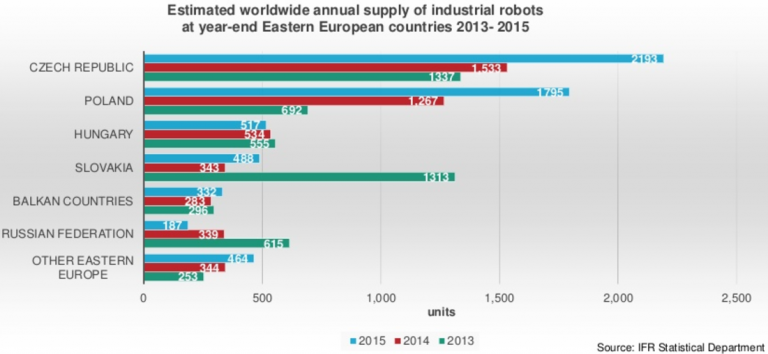

The IFR 2016 World Robotics report also mentions that the most important increases in Europe are in the Central and Eastern European countries, with sales growth rates of around 25% in 2015.

Between 2010 and 2015, the number of newly introduced robots increased by 40% in the Czech Republic (compound annual growth rate) and by 26% in Poland.

The forecasted average growth is about 14% per year between 2017-2019, according to the report.

The strongest growth rate is registered though in China, where it is estimated that, in 2019, about 40% of the world’s volume of industrial robots will be sold.

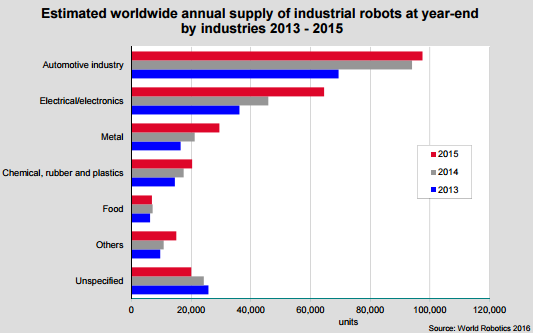

By sectors, almost 70% of the industrial robots existing in 2015 were functioning in the automotive sector, electrical/electronics industry and metal industry and in certain machine building sectors.

By country, 75% of global sales in 2015 were in China, South Korea, Japan, the United States and Germany.

By country, 75% of global sales in 2015 were in China, South Korea, Japan, the United States and Germany.

South Korea deserves a special mention, a country that leads in all the robotics related rankings (except for the automotive field, where it is exceeded by Japan). A country with a high degree of digitization and outstanding performance in all the international tests in education, especially in mathematics and science.